Serial port settings

Configuration parameters for the serial communication between ECT and the AMC console.

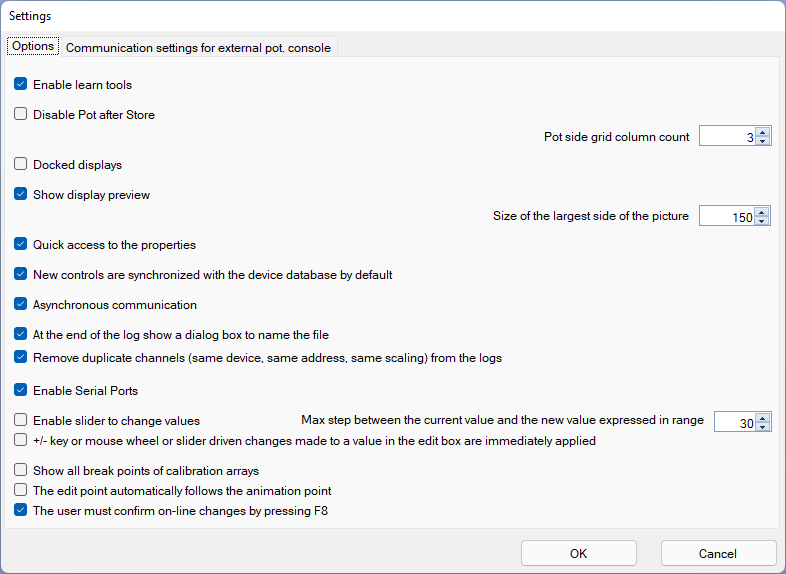

Options

Enable learn tools

Enables the functions to manage the learn – significant for devices that provide it.

Disable POT after store

If checked causes the disabling of the potentiometers after a store.

Pot side grid column count

Allows you to indicate the number of columns of the grid showing the values of the calibration map next to the potentiometer. This figure affects the overall size of the potentiometer control.

Docked windows

Allows you to use a view mode in which the loaded screens always occupy all available space. The relative position of the screens can be changed with drag and drop operations. In this view mode, the controls are displayed vertically and if it is not possible to see all the controls due to space constraints, a vertical scroll bar is activated.

Show display preview

Enables saving a thumbnail image of the display every time you save it. The image is saved in jpeg format in the same folder where the display file is stored. The parameter Size of the largest side of the picture

Allows to adjust the image size. The saved images are shown as a preview of the display when hovering over the menu item.

Quick access to the properties

By default, to access the properties of a control by double clicking, it is necessary that the display is first set in edit mode. Enabling this parameter allows access to the property page even if the edit mode is not still set; when you double click the control the edit mode is automatically set and the Property page is opened immediately.

New controls are synchronized with the device database by default

Each channel used as the data source of a view control has properties inherited from the device database. Among these properties are the scaling, the texts to be displayed, etc. It is possible to modify and customize these properties but it is usually preferable to keep an alignment with the properties inherited from the device also to be sure that any property corrections made in a device database are automatically reflected on all screens that contain channels derived from that device. For this reason, in each control it is possible to indicate whether the properties must be aligned with the properties of the device or whether they can be customized.

This option enables the alignment to the device database of the properties of the data source channels of the new controls by default. Existing controls are not affected by changing this option.

Asynchronous communication

If you enable this option, the communication operations with the device take place in a separate thread from the graphics management one.

If the K-line protocol is used, the use of asynchronous communication drastically improves the reading frequency.

At the end of the log task it shows a dialog box to name the file

By default, the name of the files in which the acquisition data are saved are defined automatically. If this option is enabled, at the end of the log task the user is shown a dialog box in which the user can specify a custom file name.

Remove duplicate channel (same device, same address, same scaling) from the log file

It may happen that the same channel has been inserted in different screens and that these screens are loaded and enabled for acquisition. In this condition, if an acquisition is performed, the same channel value could be replicated multiple times in the log file. This option can eliminate this unnecessary repetition.

Enable serial ports

Serial ports enabling

Enable slider to change values

A double click on the text box showing the value of a channel allows the enabling of the manual modification of a value. If the channel address is enabled for writing, the new value entered is written to the control unit.

The default method for changing the value is to write the value in the text box but there is an alternative method that makes use of a slider.

This option enables the use of a slider to dynamically change the value of a channel.

Max step between the current value and the new value expressed in range %

This option relates to the use of the slider and is used to limit the amplitude of a single modification of the value made using the slider.

+-key or mouse wheel or slider driver changes mad eto a value in the edit box are immediately applied

When you change the value of a channel by typing the new value in the text box, to confirm the value and try to write to the control unit it is necessary to use the enter key.

Similarly, when changing a value with the + and – buttons, with the mouse wheel or the slider, the same confirmation method is required.

This option activates a faster working method that does not require the use of the enter key to confirm if the modification is made with the + and – keys, with the mouse wheel or with the slider.

Show all break points of calibration arrays

The parameter concerns screens defined as containers of calibration elements. If a curve or map is loaded in a display of this type, it may have some disabled break points. By default the disabled break point are made invisible but enabling this parameter let you see them all.

The edit point automatically follows the animation point

The parameter affects screens defined as containers of calibration elements. If a curve or map is loaded in a screen of this type and communication with the control unit is active, it is possible to enable the animation of the breakpoints, i.e. it is possible to see which point of the curve or map is active according to the values of the breakpoints . The edit point, on the other hand, is independent and is the cell selected by the user.

By activating this option, the edit point is automatically moved to the animation point.

The user must confirm on-line changes by pressing F8

The parameter affects windows defined as containers of calibration elements. If a curve or map is loaded in a screen of this type, the changes to the values of the curve or map are not immediately transmitted to the control unit but the user must use the F8 command to transmit the changes.

By activating this option, the changes are immediately transmitted to the control unit without further confirmation.

Click OK to confirm the changes.